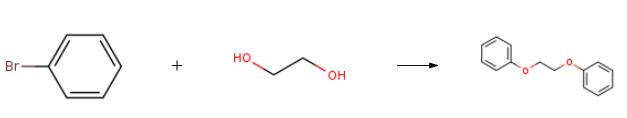

1,2-Diphenoxyethane synthesis

- Product Name:1,2-Diphenoxyethane

- CAS Number:104-66-5

- Molecular formula:C14H14O2

- Molecular Weight:214.26

591-50-4

505 suppliers

$10.00/1g

107-21-1

1369 suppliers

$10.00/25g

104-66-5

240 suppliers

$5.00/250mg

Yield:104-66-5 94%

Reaction Conditions:

with [2,2]bipyridinyl;copper(l) iodide;sodium carbonate in N,N-dimethyl-formamide at 100;

Steps:

6 Example 6

A three-necked flask was charged with 20.4 g of iodobenzene (100 mmol) and 47 ml of DMF, and stirred. 12.7 g of sodium carbonate (120 mmol, 1.2 eq.), 1.9 g of cuprous iodide (10 mmol, 0.1 eq.), 1.87 g of 2,2'-bipyridine (12 mmol, 0.1 eq.) and 7.4 g of ethylene glycol (120 mmol, 1.2 equivalent), the reaction mixture was stirred at 100 ° C overnight. After recovering DMF under reduced pressure, 100 ml of water and 100 ml of toluene were added, and the aqueous phase was extracted three times with 300 ml of toluene, and the organic layers were combined. Washed sequentially with 5% sodium carbonate. The organic phase was dried over anhydrous sodium sulfate, filtered, and then filtered and evaporated,The crude product was recrystallized from isopropanol and dried in vacuo to give 20.1 g of product, yield 94%, purity over 99%.

References:

CN110041176,2019,A Location in patent:Paragraph 0028; 0029

108-86-1

519 suppliers

$10.00/5g

107-21-1

1369 suppliers

$10.00/25g

104-66-5

240 suppliers

$5.00/250mg

107-06-2

437 suppliers

$14.00/25g

108-95-2

765 suppliers

$14.00/25g

104-66-5

240 suppliers

$5.00/250mg

107-21-1

1369 suppliers

$10.00/25g

108-90-7

671 suppliers

$10.00/25G

104-66-5

240 suppliers

$5.00/250mg

108-95-2

765 suppliers

$14.00/25g

622-86-6

165 suppliers

$5.00/5g

104-66-5

240 suppliers

$5.00/250mg