POLY(COUMARONE-CO-INDENE)

|

|

POLY(COUMARONE-CO-INDENE) Eigenschaften

- Dichte

- 1.14 g/mL at 25 °C(lit.)

- Flammpunkt:

- >230 °F

- Aggregatzustand

- flakes

- EPA chemische Informationen

- Benzofuran, polymer with 1H-indene (35343-70-5)

Sicherheit

| WGK Germany | 3 |

|---|

POLY(COUMARONE-CO-INDENE) Chemische Eigenschaften,Einsatz,Produktion Methoden

synthetische

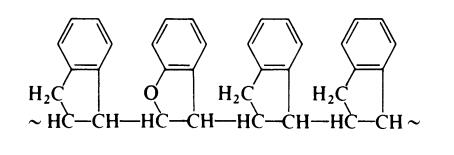

Coumarone (benzofunin) (I) and indene (II) occur in coal tar naphtha (b.p. 150-200??C) together with various other compounds (mainly xylenes and cumenes). In the preparation of polymers, no attempt is made to isolate these monomers and they are polymerized in situ. Indeed, resinification is used as a means of separating these substances from the other components of the cut which are subsequently distilled and sold as solvents. Polymerization of the coumarone-indene mixture is accomplished by adding concentrated sulphuric acid to the naphtha at 0??C. Reaction is stopped after 5-10 minutes by the addition of water and any sludge is removed. The solution is then neutralized and washed and residual napththa is distilled off to leave the resin. Depending on the relative proportions of coumarone and indene (the coumarone content is usually less than 10%) and the polymerization conditions, resins may vary from hard and brittle to soft and sticky materials. The resins have molecular weights of about 1000-3000 and are commonly assumed to be a random copolymer of the following type:

Coumarone-indene polymers are chemically inert and are used as binders in cheaper grades of floor tiles. They are also used as additives in various surface coating formulations.

POLY(COUMARONE-CO-INDENE) Upstream-Materialien And Downstream Produkte

Upstream-Materialien

Downstream Produkte

POLY(COUMARONE-CO-INDENE) Anbieter Lieferant Produzent Hersteller Vertrieb H?ndler.

Global( 4)Lieferanten

| Firmenname | Telefon | Land | Produktkatalog | Edge Rate | |

|---|---|---|---|---|---|

| N SHASHIKANT & CO. | -- |

n4salesforce@gmail.com | India | 83 | 58 |

| Riedel-de Haen AG | -- |

United States | 6773 | 87 | |

| SIGMA-RBI | -- |

Switzerland | 6896 | 91 | |

| Guangzhou WeiBo Chemical Co., Ltd. | -- |

weibochem@163.com | China | 6187 | 67 |

35343-70-5()Verwandte Suche:

Inden

Tris(pentan-2,4-dionato)eisen(II)

(Ethylenbis(nitrilomethylidyn)-2,2'-diphenolato)cobalt(II)

Aluminiumtris(2,4-pentandionato-O,O')

Tris(2,2,6,6-tetramethylheptan-3,5-dionato-O,O')dysprosium

Ethylisocyanacetat

1,1,3,3-Tetramethylbutylisocyanat

Dichloro(ethylendiamin)platin

Phenylselenol

2-Methylpropylisocyanid

Benzylisocyanid

Kupfer(II)-4-oxopent-2-en-2-olat

Methylisocyanacetat

N-Butylisocyanid

(Pentan-2,4-dionato-O,O')silber

(p-Toluolsulfonyl)methylisocyanid

Tris(2,2,6,6-tetramethylheptan-3,5-dionato-O,O')europium

- Benzofuran,polymerwith1H-indene

- Coumarone,indeneresin

- coumarone-indene

- coumarone-indeneresin

- Poly(indene-co-coumarone)

- POLY(INDENE-CO-COUMARONE) AVERAGE MN &

- POLY(COUMARONE-CO-INDENE)

- 1-benzofuran,1H-indene

- 35343-70-5

- Polymers