POLY(4-METHYL-1-PENTENE) Chemische Eigenschaften,Einsatz,Produktion Methoden

S-S?tze Betriebsanweisung:

S24/25:Berührung mit den Augen und der Haut vermeiden.

Chemische Eigenschaften

Poly(4-methyl-1-pentene) was first introduced in 1965 by Imperial Chemical

Industries Ltd (UK) but since 1975 the polymer has been manufactured solely

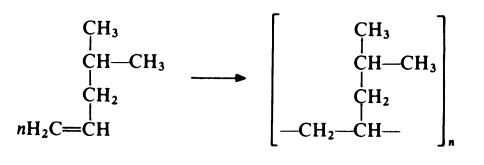

by Mitsui Petrochemical Industries Ltd. Polymerization is carried out using

a Ziegler-Natta catalyst such as titanium trichloride/diethylaluminium chloride in a hydrocarbon diluent at atmospheric pressure and 30-60°C:

The commercial material contains a comonomer, possibly 1-hexene, which

enhances clarity. The polymer configuration is predominantly isotactic.

Generally, this material has the basic physical properties to be expected

from a crystalline polyolefin but in some respects it offers significant improvements over other polyolefins. One outstanding property of poly(4-methyl-l-pentene) is the very low specific gravity, which at 0.83 is the lowest of current

polymers. The crystalline melting point is 240°C and the Vicat softening

temperature is 179°C; these high values mean that a useful form stability is

maintained up to about 200°C. The transparency of the polymer is of a high

order, being comparable to poly(methyl methacrylate) and polystyrene.

Poly(4-methyl-l-pentene) exhibits resistance to oxidizing and other chemical

environments broadly similar to that shown by polypropylene; however,

poly(4-methyl-l-pentene) does undergo environmental stress cracking

comparable to low density polyethylene. The permeability of poly(4-methyl-I-pentene) to gases and water vapour is considerably higher than that for

other polyolefins. Poly(4-methyl-l-pentene) may be extruded and injection

moulded using standard equipment. The material has been used in several

applications where transparency and heat resistance are required, e.g. medical and laboratory ware.

Verwenden

Coating for paper food containers for microwave and conventional ovens. Release coatings for food and synthetic leather. Molded into medical labware. Film for decorative laminates and printed circuit boards.

POLY(4-METHYL-1-PENTENE) Upstream-Materialien And Downstream Produkte

Upstream-Materialien

Downstream Produkte