1-Adamantyl Methacrylate Chemische Eigenschaften,Einsatz,Produktion Methoden

Beschreibung

1-adamantyl methacrylate is a monomer that has a hydroxy group and a carbonyl group.

synthetische

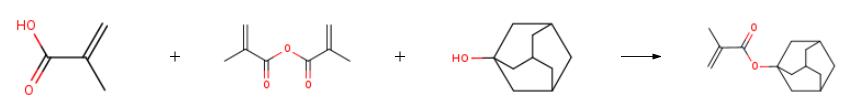

The preparation of 1-adamantyl methacrylate is as follows:Stirrer, air inlet tube,Dean-Stark type water separator,Necked flask equipped with a stirrer, a thermometer,1-Adamantanol 100 g(0.657 mol),Methoquinone0.581 g,Hydroquinone0.143 g,Methacrylic acid227 g (2.64 mol) andMethylcyclohexaneWas added.After adding 1.61 g (0.0164 mol) of concentrated sulfuric acid,While blowing air at 10 mL / min, the mixture was stirred at a temperature of 100 to 115 ° C. for 4 hours under azeotropy of methylcyclohexane and water.4 hours laterThe conversion of 1-adamantanol was 95.1%.at this pointMethacrylic anhydride10.1 g (0.0657 mol / 2.0 equivalents to residual 1-adamantanol) was added,The mixture was further stirred for 1 hour,The reaction was terminated.The residual amount of 1-adamantanol after the reaction was 0.2%.The reaction solution was cooled to room temperature,313 g of a 20% by mass sodium hydroxide aqueous solution was added dropwise,The organic phase was washed.further,And washed twice with 100 mL of pure water.After distilling off the solvent with an evaporator, distillation under reduced pressure at 1 torr and 90 ° C.,122 g (yield 84.1%) of a colorless transparent liquid was obtained.This liquid was analyzed by GC and GPC.According to GC analysis1-Adamantyl acrylateThe purity of 99.5%.

Application

1-Adamantyl Methacrylate is a monomer that has a hydroxy group and a carbonyl group. It is used in the production of polymers, as well as in coatings and adhesives. 1-Adamantyl Methacrylate can be thermally polymerized or crosslinked to form a polymer with high resistance to radiation and heat.This monomer has been used for the fabrication of organic light emitting diodes (OLEDs) and other device applications such as microelectronic circuits, solar cells, and displays.

Research

1-Adamantyl methacrylate (AdMA) could be polymerized using the atom transfer radical polymerization (ATRP) method with methyl α-bromoisobutyrate (MBiB), copper(I) bromide (CuBr), copper(II) bromide (CuBr2) and 1,1,4,7,10,10-hexamethyltriethylenetetramine (HMTETA) in toluene at 60?°C, producing well-defined poly(1-adamantyl methacrylate) (PAdMA). The controlled/living radical polymerization of methacrylate monomers bearing bulky ester groups, such as AdMA, which guarantees the generation of well-defined macromolecular architectures such as the block copolymer, graft copolymer and star-shaped polymer on a preparative scale, is still of great interest[1].

1-Adamantyl Methacrylate Upstream-Materialien And Downstream Produkte

Upstream-Materialien

Downstream Produkte