Methoxyethene synthesis

- Product Name:Methoxyethene

- CAS Number:107-25-5

- Molecular formula:C3H6O

- Molecular Weight:58.08

A. Acetylene undergoes a nucleophilic addition reaction with methanol in the presence of a strong base to produce MVE. The original Reppe process was carried out at a temperature of 160–165 °C under a 2–2.2 MPa pressure. The most commonly used catalyst for this reaction was an alkali metal hydroxide or an alkali metal alkoxide. Acetylene was usually diluted by nitrogen. However, this process requires high temperature and high pressure, leading to a safety problem in handling acetylene gas under such conditions. Another method is an equimolar mixture of acetylene gas and vaporized methanol, which is introduced into a fixed-bed reactor filled with a ZnO/SiO2 catalyst. The reaction temperature was in the range of 200 to 270 °C. MVE is the main product, and a significant amount of by-product (dimethoxyethane) was also generated by an equilibrium reaction of MVE and methanol to dimethoxyethane.

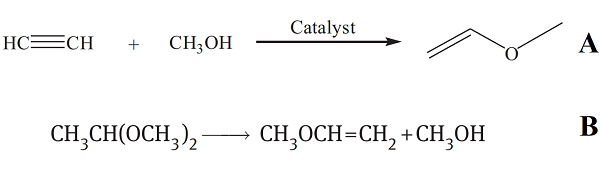

A. Acetylene undergoes a nucleophilic addition reaction with methanol in the presence of a strong base to produce MVE. The original Reppe process was carried out at a temperature of 160–165 °C under a 2–2.2 MPa pressure. The most commonly used catalyst for this reaction was an alkali metal hydroxide or an alkali metal alkoxide. Acetylene was usually diluted by nitrogen. However, this process requires high temperature and high pressure, leading to a safety problem in handling acetylene gas under such conditions. Another method is an equimolar mixture of acetylene gas and vaporized methanol, which is introduced into a fixed-bed reactor filled with a ZnO/SiO2 catalyst. The reaction temperature was in the range of 200 to 270 °C. MVE is the main product, and a significant amount of by-product (dimethoxyethane) was also generated by an equilibrium reaction of MVE and methanol to dimethoxyethane. B. MVE is prepared by pyrolysis of dimethyl acetal at high temperature in the presence of a solid catalyst. In general, the pyrolysis of dimethylacetal is carried out in the vapor phase. Dimethylacetal was vaporized and introduced into a fixed-bed reactor filled with calcium phosphate catalyst. In the reactor, dimethylacetal split into MVE and methanol at 320 °C and under atmospheric pressure. The conversion of dimethylacetal was 95%, and the selectivity to MVE was more than 98%.

Yield:-

Reaction Conditions:

with magnesium oxide at 400;Inert atmosphere;Reagent/catalyst;

Steps:

1-6 Magnesium oxide catalyst catalyzes ethylene glycol dimethyl ether to prepare vinyl methyl ether.

In a miniature atmospheric fixed-bed reactor, ethylene glycol dimethyl ether with a space velocity of 1h-1 is introduced, nitrogen is used as a balance gas, and 0.5g of magnesium oxide is used as a catalyst. The reaction was carried out at 400° C., the conversion rate of ethylene glycol dimethyl ether was 22.5%, the molar selectivity of vinyl methyl ether was 84.3%, and the molar selectivity of methanol was 76.9%.

References:

Peking University;Liu Haichao;He Xin CN111807937, 2020, A Location in patent:Paragraph 0029-0043

7252-83-7

419 suppliers

$5.00/10g

107-25-5

108 suppliers

inquiry

98577-44-7

222 suppliers

$10.00/1g

107-25-5

108 suppliers

inquiry

1120-56-5

43 suppliers

$140.00/1g

![bicyclo[1.1.1]pentane](/CAS/20180702/GIF/311-75-1.gif)

311-75-1

2 suppliers

inquiry

![Tricyclo[1.1.1.01,3]pentane](/CAS/GIF/35634-10-7.gif)

35634-10-7

13 suppliers

inquiry

74-86-2

76 suppliers

inquiry

107-25-5

108 suppliers

inquiry