Obolactone Chemische Eigenschaften,Einsatz,Produktion Methoden

Synthese

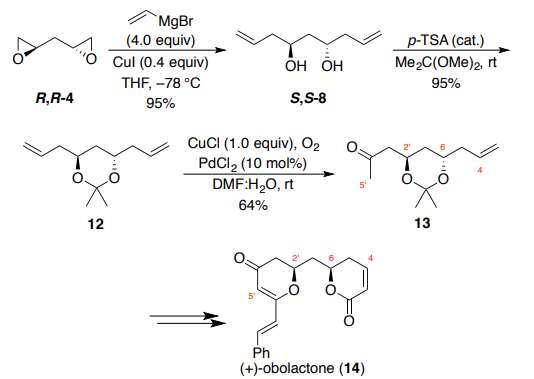

The synthesis of (+)-obolactone (14, Scheme 3) by Brückner and Walleser

employed the same conditions from the synthesis of 17-deoxyroflamycoin to transform bis-epoxide R,R-4 to bis-homoallylic diol S,S-8. Diol 8 was then

protected using 2,2-dimethoxypropane under acidic conditions to provide

acetonide 12 in 95% yield. One of the alkene functional groups of the C2-

symmetric acetal underwent a subsequent symmetry-breaking Wacker

oxidation. Treatment of acetonide 12 with catalytic PdCl2 under an

atmosphere of oxygen using CuCl as the stoichiometric oxidant afforded a

64% yield of methyl ketone 13, with over-oxidation to the diketone also

observed (18% yield). The methyl ketone functionality of 13 was critical for

the installation of the dihydro-g-pyranone moiety in the natural product,

while the syn-orientation of the C–O bonds was achieved through Mitsunobu

inversion of the lactone stereocenter. Brückner and Walleser specifically

mention that while Krische and co-workers have reported on an impressive

single-step procedure for the catalytic enantioselective synthesis of bishomoallylic diol (S,S-4) from 1,3-propanediol, and have used

this method extensively in the synthesis of polyketide natural products,

21,22

the high cost of catalyst and ligand precluded their use on scale in this case.

Obolactone Upstream-Materialien And Downstream Produkte

Upstream-Materialien

Downstream Produkte