Polystyrene,rubber modified Chemische Eigenschaften,Einsatz,Produktion Methoden

Verwenden

A serious limitation of polystyrene in many applications is its brittleness and

a number of attempts have been made to improve the polymer in this respect.

The most successful approach to this problem has been the addition of

rubbery materials (usually 5-15%) to the polymer and rubber-modified

polystyrene (commonly referred to as impact polystyrene) is an important

commercial material. In fact, production of impact polystyrene currently

exceeds that of crystal polystyrene. Several rubbers have been tried for the

preparation of impact polystyrene but cis-1,4-polybutadiene is the most

commonly used. The method of mixing the polystyrene and rubber has a

profound effect on the properties of the product. Simple blending of the two

polymers in, for example, an internal mixer or two-roll mill gives a product which has only slightly better impact strength than straight polystyrene.

Likewise, the mixing of the polymers in latex form and isolation of the

product by coagulation results in only marginal improvement. However,

much better results are obtained if the polystyrene is prepared in the presence

of the rubber. In one commercial process, for example, rubber is dissolved in

a styrene-solvent mixture and then the styrene is polymerized in solution. The products of

such methods contain not only polystyrene and straight rubber but also a

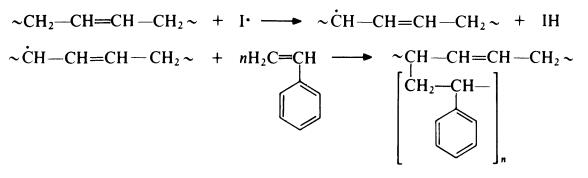

graft polymer in which polystyrene side chains are attached to the rubber:

where I? is an initiator fragment.

Compared to straight polystyrene, rubber-modified polystyrenes have

much improved impact strength, but they have reduced clarity, softening

point and tensile strength.

Polystyrene,rubber modified Upstream-Materialien And Downstream Produkte

Upstream-Materialien

Downstream Produkte