| Identification | Back Directory | [Name]

POLY(METHYL METHACRYLATE) | [CAS]

9011-14-7 | [Synonyms]

50n

lpt

st1

so95

lpt1

ao10

dv400

k120n

a21lv

lso-m

korad

sol90

sol95

so120

so140

torexg

vedril

pmma-a

Lucryl

LUCITE

acrypet

lso-m4b

perspex

mh101-2

palacos

vedril5

vedril8

tensol7

romacryl

paraglas

lucite30

lucite47

acrypetv

diakonmg

disapolm

elvacite

Acrylite

acrypetvh

delpet50m

delpet60n

delpet80n

lucite120

lucite129

lucite130

lucite140

lucite147

lucite180

osteobond

pontalite

repairsin

plexiglas

sumipexlg

sumipexlo

Zimmer DT

Zimmer LVC

PMMACEMENT

sumipexmho

shinkolite

rhoplexb85

plex8572-f

parapet60n

metaplexno

crinothene

altulorm70

degalans85

acrysolase

kallocrylk

kaneacepa20

diakonmg101

acrypetm001

diakonlo951

resarit4000

superacrylo

stellonpink

sumipexb-lg

sumipexb-mh

sumipex-bmhd

superacrylae

plexigumm920

st1(polymer)

paraplexp543

paraplexp681

akuripettovh

kallodent222

elvacite2008

elvacite2009

elvacite2010

elvacite2021

elvacite2041

elvacite6011

elvacite6012

acryloida-15

acronals320d

50n(polymer)

Acryloid A-30

Acryloid B-44

cmwbonecement

metaplex4002t

organicglasse2

degalanlp59/03

kallodentclear

Paraloid K-120N

surgicalsimplex

surgicalsimplexp

Zimmer Dough Type

Zimmer Bone Cement

Zimmer Low Viscosity

Poly(Methyl Methacryla

METHYLPOLYMETHACRYLATE

METHYL METHACRYLATE RESIN

POLY(METHYL METHACRYLATE)

Polymethacrylate: (Lucite)

Polymer solid microspheres

METHYL METHACRYLATE POLYMER

osteobondsurgicalbonecement

METHYLACRYLICACIDMETHYLESTER

methylmethacrylatehomopolymer

Methyl methacrylate copolymer

POLY(METHYL METHACRYLATE) 600

POLYMETHYL METHACRYLATE BEADS

POLYBEAD(R) PMMA MICROSPHERES

POLY(METHYL METHACRYLATE) 8'000

POLY(METHYL METHACRYLATE) 2'000

POLY(METHYL METHACRYLATE) 5'000

Methyl methacrylate homopolymer

PolyMethyl Methacrylate, Powder

Poly(methyl methacrylate)(PMMA)

Leco Lucite Thermoplastic Powder

POLYMETHYLMETHACRYLATEBONECEMENT

POLY(METHYL METHACRYLATE) 50'000

POLY(METHYL METHACRYLATE) 20'000

METHYL METHACRYLATE, POLYMERIZED

POLY(METHYL METHACRYLATE) 10'000

POLY(METHYL METHACRYLATE) 75'000

POLY(METHYL METHACRYLATE) 800'000

POLY(METHYL METHACRYLATE) 100'000

POLY(METHYL METHACRYLATE) 150'000

POLY(METHYL METHACRYLATE) 500'000

POLY(METHYL METHACRYLATE) 300'000

Poly(methyl methacrylate), pract.

methacrylicacidmethylesterpolymers

POLY(METHYL METHACRYLATE) 2'480'000

poly(methacrylic acid methyl ester)

poly(methylmethacrylate), 600 micron

POLY(METHYL METHACRYLATE), ISOTACTIC

METHACRYLIC ACID METHYL ESTER POLYMER

Poly(methylmethacrylate) high mol.wt.

poly(Methacrylicacidmethylester),PMMA

METHYL METHACRYLATE RESIN (LOW M.WT.)

Poly(methyl methacrylate), M.W. 93300

METHYL METHACRYLATE RESIN (HIGH M.WT.)

POLY(METHYL METHACRYLATE) STANDARD 600

Poly(methyl methacrylate), MW ≈ 550,000

poly(methyl methacrylate) macromolecule

POLY(METHYL METHACRYLATE) STANDARD 8'000

Poly(methyl methacrylate) Standard 4'000

Polymethyl methacrylate superfine powder

POLY(METHYL METHACRYLATE) STANDARD 2'000

POLY(METHYL METHACRYLATE) STANDARD 20'00 0

POLY(METHYL METHACRYLATE) STANDARD 50'00 0

POLY(METHYL METHACRYLATE) STANDARD 10'00 0

POLYMETHYLMETHACRYLATE(IMPLANTSANDCEMENTS)

POLY(METHYL METHACRYLATE) STANDARD 75'00 0

POLY(METHYL METHACRYLATE) STANDARD 24800 00

POLY(METHYL METHACRYLATE) STANDARD 100'0 00

POLY(METHYL METHACRYLATE) STANDARD 150'0 00

POLY(METHYL METHACRYLATE) STANDARD 200'0 00

POLY(METHYL METHACRYLATE) STANDARD 500'0 00

POLY(METHYL METHACRYLATE) STANDARD 800'0 00

POLY(METHYL METHACRYLATE-CO-ETHYL ACRYLATE)

Polymethyl methacrylate,tooth bracket powder

PMMA, Poly(methacrylic acid methyl ester)

Poly(methyl methacrylate), nominal M.W. 38000

POLY(METHYL METHACRYLATE), SECONDARY STA NDARD

2-methyl-2-propenoicacidmethylesterhomopolymer

POLY(METHYL METHACRYLATE), AVERAGE M.W. 120,000

2-Propenoicacid,2-methyl-,methylester,homopolymer

POLYBEAD(R) POLY(METHYL METHACRYLATE) MICROSPHERES

POLY(METHYL METHACRYLATE), AVERAGE MW CA . 350,000

Poly(methyl methacrylate), approx. M.W. 15000 (GPC)

Poly(methyl methacrylate), Average M.W. 15000 (GPC)

Poly(Methyl Methacrylate) average Mw ~350,000 by GPC

Poly(Methyl Methacrylate) average Mw ~120,000 by GPC

Poly(methyl methacrylate), beads, average M.W. 35000

950 MW, polymethylmethacrylate (PMMA) plasticizer free

2-Propenoic acid, 2-methyl-, methyl ester, homopolymer

POLY(METHYL METHACRYLATE), AVERAGE MW CA . 15,000 (GPC)

POLY(METHYL METHACRYLATE), AVERAGE MW CA . 996,000 (GPC)

Poly(Methyl Methacrylate), average Make.W. 15,000 by GPC

Poly(Methyl Methacrylate), beads, average M.W. 35,000 25GR

MALDI VALIDATION SET POLY(METHYL METHA-C RYLATE) CERTIFIED

Poly(Methyl Methacrylate) average Mw ~15,000 by GPC, powder

Methacrylic Acid Methyl Ester Polymer

Poly(methyl Methacrylate)

Poly(Methyl Methacrylate) average Mw ~996,000 by GPC, crystalline

Poly(methyl methacrylate),PMMA, Poly(methacrylic acid methyl ester)

PMMA, Poly(methacrylic acid methyl ester), Poly(methyl methacrylate)

Poly(methyl methacrylate) inherent viscosity ~1.25 dL/g (lit.), crystalline

Poly(methyl methacrylate), sec. stand., MW 97.000, M.N. 44.700, fine granules

Poly(Methyl Methacrylate), sec. stand., M.W. 97000, M.N. 44700, fine granules 25GR

maldi validation set poly(methyl methacrylate) mp 500-70'000 certified according to din

Poly(methacrylic acid methyl ester) PMMA Methyl methacrylate, polymerized Methyl Methacrylate Polymer Methacrylic Acid Methyl Ester Polymer | [EINECS(EC#)]

201-297-1 | [Molecular Formula]

C15H24O6X2 | [MDL Number]

MFCD00134349 | [MOL File]

9011-14-7.mol | [Molecular Weight]

300.35 |

| Chemical Properties | Back Directory | [Appearance]

white powder (or clear plastic sheet) | [Melting point ]

150 °C

| [Boiling point ]

108 °C | [density ]

1.188 g/mL at 25 °C | [Tg]

115 | [Tg]

88 | [refractive index ]

n20/D 1.49

| [Fp ]

250 °C | [storage temp. ]

2-8°C | [solubility ]

alcohols and aliphatic hydrocarbons: insoluble

| [form ]

powder

| [color ]

White | [Specific Gravity]

1.188 | [Stability:]

Stable. Combustible. Incompatible with strong oxidizing agents. | [Water Solubility ]

Soluble in tetrahydrofuran, toluene, cyclohexanone, ethyl acetate and chloroform. Insoluble in water, alcohols and aliphatic hydrocarbons. | [LogP]

1.346 (est) | [CAS DataBase Reference]

9011-14-7 | [IARC]

3 (Vol. 19, Sup 7) 1987 | [EPA Substance Registry System]

Methyl methacrylate homopolymer (9011-14-7) |

| Hazard Information | Back Directory | [Chemical Properties]

white powder (or clear plastic sheet) | [Definition]

ChEBI: A macromolecule composed of repeating methyl methacrylate units. | [Description]

Methyl methacrylate is one of the most common

methacrylates. This acrylic monomer, the essential

component of the fluid mixed to the powder, may

cause allergic contact dermatitis mainly in dental

technicians and dentists. Cases were also reported in

those using seulptured nails and in ceramics workers. | [Uses]

PMMA/HA (Hydroxyapatite) composites have be used in biomedical applications such as dentistry, orthopedic retainers, and bone replacement. It has been used as substrate for graphene growth.

Some studies report its use as

PMMA-titania hybrid optical thins films

PMMA/polystryrene/clay nanocomposites

PMMA/polyurethane/carbon black nanocomposites for methanol fuel cells. | [Uses]

Poly(methyl methacrylate) may be used as a reference suspension polymer for the analysis of the composition of poly(methyl methacrylate) (PMMA) by gas chromatography method. | [Uses]

Poly(methyl methacrylate) is used in production of Carbonate-olefin based copolymer for molded plastics. | [Preparation]

The polymerization of methyl methacrylate:

is readily accomplished by bulk, solution, suspension and emulsion techniques. Of these methods, bulk and suspension polymerization are mainly used

for the production of the homopolymer.

(a) Bulk polymerization

Techniques which involve a combination of bulk polymerization and casting

are extensively used in the manufacture of poly(methyl methacrylate) sheet.

In most processes, the first step is the preparation of a partially polymerized

material. Typically, monomer is stirred with benzoyl peroxide (0.5%) at 90??C

for about 10 minutes to give a syrup which is then cooled to room temperature. Colourant, plasticizer and ultraviolet absorber, if required, are added at

this point. At this stage the degree of conversion of monomer to polymer is

about 20%; the use of such a syrup reduces shrinkage in the casting cell and

also lessens leakage from the cell. The syrup is then poured into a casting cell,

consisting of two glass plates separated by a rubber gasket. The plates are

held together by spring-loaded clamps so that the plates continuously move

together in response to the shrinkage of approximately 20% which occurs on

conversion of monomer to polymer. The filled cell is then passed through a

heating tunnel wherein the temperature is maintained at 40??C for 15 hours and then 95??C for 1 hour. The sheet is then cooled and removed from the cell.

With castings of thickness greater than about 2 cm, the exothermic reaction

may result in local temperatures above the boiling point of the monomer

(100Se) and bubbles may form. In such cases, polymerization may be

carried out under pressure so that the boiling point of the monomer is raised.

Rod is also manufactured by casting. In one process, syrup is contained in

vertical aluminium tubes which are very slowly lowered into a bath at 40??C.

As the lowest portion of syrup polymerizes it contracts and the syrup above

moves downwards. In this way a homogeneous rod, free from voids, is

obtained. Dentures are normally made from a polymer-monomer dough in a

plaster mould. Bulk polymerization carried out in the preparation of sheet, as

described above, results in polymer of very high average molecular weight

(??106).

(b) Suspension polymerizution

Suspension polymerization of methyl methacrylate is used mainly for the

production of injection moulding and extrusion grades of polymer. Suspension polymer is also used in the preparation of polymer-monomer doughs for

dentures. Polymerization is carried out batch-wise in a stirred reactor,

jacketed for heating and cooling; the reactor is capable of withstanding a

pressure of 0.3--0.4 MPa (3-4 atmospheres).

Reaction is carried out under nitrogen. Typically, the mixture is initially

heated to about 80??C but the exothermic reaction causes the temperature to

rise to about 120??C, with accompanying increase in pressure. Polymerization

is rapid and is complete in about 1 hour. The suspension is cooled and

acidified with sulphuric acid to remove the suspending agent. The beads of

polymer are then filtered off, washed and dried in air at about 80??C. The dried

beads may be used for moulding without further treatment or they may be

compounded with additives (e.g. colourants), extruded and granulated.

Suspension polymerized poly(methyl methacrylate) normally has an average molecular weight of about 60000. | [General Description]

Poly (methyl methacrylate) (PMMA) is an amorphous transparent thermoplastic polymer. PMMA is recognized as an optical polymer based on its refractive index of 1.49. Hence, it is used in optical fibers.It finds uses in biological applications because of its low water absorption capability and biocompatible.The maximum moisture content of PMMA is 1.71% and SBF absorption is 1.96%.Simulated Body fluid test (SBF) is a method to characterize the in vitro bioactivity of ceramic materials, by immersing the materials in an aqueous SBF solution. | [Solubility in organics]

Acetone, benzene, chloroform, MEK, THF |

| Safety Data | Back Directory | [Hazard Codes ]

Xn | [Risk Statements ]

20/22 | [Safety Statements ]

36-24/25-22 | [WGK Germany ]

3

| [RTECS ]

TR0400000

| [Autoignition Temperature]

580 °F | [TSCA ]

Yes | [HS Code ]

39061000 | [Safety Profile]

Questionable

carcinogen with experimental tumorigenic

data by implant route. When heated to

decomposition it emits acrid smoke and

irritating fumes. Used as the main

constituent of acrylic sheet, moldmg, and

extrusion powders. |

| Questions And Answer | Back Directory | [Overview]

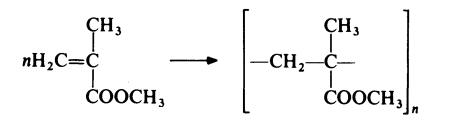

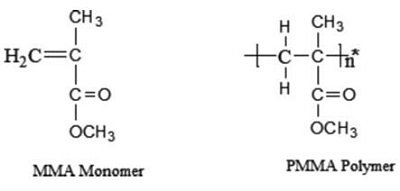

Poly (methyl methacrylate) (PMMA), having the IUPAC name of poly [1-(methoxy carbonyl)- 1-methyl ethylene] from the hydrocarbon standpoint, and poly (methyl 2-methylpropenoate) from the ester standpoint, is a synthetic polymer from the methyl methacrylate monomer as illustrated in Figure 1.[1] PMMA was discovered in the early 1930s by British chemists, Rowland Hill and John Crawford, followed by its first application by a German chemist, Otto Rohm, in 1934.[2] PMMA is an optically clear (transparent) thermoplastic, and it is widely used as a substitute for inorganic glass, because it shows high impact strength, is lightweight, shatter-resistant, and exhibits favorable processing conditions.[3] Outstanding properties include weather resistance and scratch resistance. The presence of the adjacent methyl group (CH3) in the polymer structure prevents it from packing closely in a crystalline fashion, and from rotating freely around the C-C bonds. This is why PMMA was found to be an amorphous thermoplastic. The first major application of the polymer took place during World War II, when PMMA was used as aircraft windows and bubble canopies for gun turrets.

Figure 1 the chemical structure of PMMA

PMMA is a promising polymer for applications in optical, pneumatic actuation, sensor, analytical separation, and conductive devices.[4–8] Other applications include the use of PMMA in biomedical applications, polymer electrolytes, polymer viscosity, and drug delivery using electro-diffusion or electro-osmotic flow.[9–13] Due to its compatibility and easy processing as a polymer moiety, PMMA with carbon nanotubes or other inorganic materials plays an important role in the development of nanotechnology. Wang et al., in the preparation of carbon nanotube polymer composites, used poly (styrene-co-acrylonitrile) with poly (methyl methacrylate)-g-multi walled carbon nanotubes.[14] | [Production method]

PMMA can be obtained from its monomer using different techniques of polymerization. The monomer undergoes polymerization using the common methods of free radical and anionic initiations by bulk, solution, suspension, and emulsion techniques. [15] Following the discovery of a new technique of polymerization by Krzysztof Matyjaszewski in 1995[16] called Atom Transfer Radical Polymerization (ATRP), Matyjaszewski et al. successfully polymerized the monomer of methyl methacrylate (MMA) to produce PMMA as a living polymer with 80% conversion, poly-dispersity as low as 1.1, and an Mn of 20,000 in a few hours.[17]

| [Physicochemical properties]

PMMA is one of the amorphous polymers that belong to the acrylate family. It is a clear, colorless polymer with a glass transition temperature range of 100 degree to 130 degree, and a density of 1.20 g/cm3 at room temperature. This polymer melts at 130 degree, with a water absorptivity of 0.3%, moisture absorption at equilibrium of 0.3 to 0.33%, and a linear shrinkage mold of 0.003 to 0.0065 cm/cm[18-20].

PMMA is among the polymers that have high resistance to sunshine exposure because it has a small variation under the effect of UV-radiation. It has very good thermal stability, and is known to withstand temperatures as high as 100 degree and as low as 70 degree.

It also possesses very good optical properties, with a refractive index of 1.490, and a good degree of compatibility with human tissue.[18, 19]

PMMA is an organic polymer, and its solubility is expected to be governed by “like-dissolve-like,” with polarity playing a major role. PMMA shows little deviation, as its solubility is more complex, starting with swelling in the solvent and the subsequent formation of a very soft layer on its surface. This is then followed by diffusion of the solvent into the whole polymer before it gives a homogenous solution with the solvent. This is the reason why PMMA takes a few minutes before it is dissolved completely, even if it is in its best solvent.

PMMA hydrolyzed completely with sulfuric acid (H2SO4) to become poly (methacrylic acid) (PMAA). Hydrochloric acid and hydro-iodic acid are capable of hydrolyzing PMMA, but at a slow rate when compared to sulfuric acid[21]. PMMA has a predominantly elemental composition of carbon and hydrogen. Therefore, it is liable to undergo an exothermic combustion reaction to yield gaseous products (CO2, CO, H2O,) and energy like any other hydrocarbon. The thermal decomposition of PMMA has been extensively studied in the absence of oxygen. The decomposition temperature varies, depending on the approach used in the synthesis of the polymer. Radically polymerized PMMA containing terminal C-C bonds decompose at a temperature of 220 degree with simple mechanisms of monomer repeat units bond scission and C-C bond random scission [18].

| [Application]

Biomedical

PMMA has been used in the area of biomedical applications, which involves the preparation of bone cements for drug delivery/release and cranioplasty. The qualities that made the polymer a potential material for these applications include: non-toxicity, less cost, easy processability, compatibility, minimal inflammatory reactions with tissues, and greater fracture resistance, especially when used in cranioplasty.

PMMA has also been used to widen the applications of chitosan in various fields that include biomedical and pharmaceutical applications. Zuhair et al. reported the successful grafting of a PMMA/chitosan blend. The results indicated an increase in the mechanical properties, such as tensile strength and flexural modulus. The degradation, porosity, and water absorbency of the blend in synthetic body fluid (SBF) with a pH of 7.4 increased with an increase in the chitosan percentage and immersion time in SBF. These behaviors exhibited by the PMMA/chitosan blend illustrate its potentials for drug release applications[22].

Molecular Separation

Molecular separations in chemistry can be achieved in an advanced way by the use of chromatographic techniques, which involve the use of a stationary phase (inert solid support) and mobile phase (usually solvent or mixture of solvents). The common solid supports used are inorganic materials such as silica and alumina, but they have low patronage due to their disadvantages in separating some organic molecules, and limited modifications for maximum efficiency. Therefore, both natural and synthetic polymers have recently been used to replace the inorganic materials. PMMA is the most promising synthetic polymer for applications in molecular separation due to its low cost, compatibility, ease of modification, and processability[7, 23].

Optical applications

Optical science is relevant and studied in many disciplines, including engineering, medicine, pure science, and astronomy. Practical applications are found in lenses, microscopes, lasers, fibers, and polymers, to name a few. The optical activity of any material is the result exhibited by that material when interacting with light and the refractive index is the measure of that activity. The optical applications of PMMA are due to its refractive index, good resistance to UV light, chemical durability, and good mechanical properties.

Organic polymers are usually cheap, lightweight, and easily processed substrates, and are therefore good for immobilizing semiconductors for heterogeneous photocatalytic applications. Camara et al. revealed the investigation of eleven synthetic polymers susceptible to coating with TiO2 for exposure to solar radiation, with and without the TiO2 layer, for 150 days to study the weathering. They observed that only the PMMA retains good optical and mechanical properties of the Titania after natural weathering. Therefore, PMMA is the best candidate for the immobilization of TiO2 for photocatalytic treatment applications[24].

Polymer conductivity and electrolytes

Most polymers are electrical insulators. However, conducting polymers can be prepared using an insulating polymer and electrically conductive fillers called dopants. The electrical properties of PMMA doped with conducting materials under various experimental conditions including photo-induced changes, has been studied. PMMA was used as an organic insulator, while the PVA-PAA-glycerol was a semiconducting polymer. Aluminum electrodes were used as bottom and top electrodes for the fabricated devices. Finally, organic memory devices were prepared based on the Au-PtAg nanoparticles as charge storage elements. Herein, PMMA was used as the organic insulator[25].

A polymer electrolyte membrane for battery application must play the following roles: must enable positive ion transport such as Li+ between the electrodes, must block the electron transport, and must be rigid to prevent direct contact between the electrodes[26]. The application of PMMA in the polymer electrolyte was due to the amorphous nature for porosity’s sake and the mechanical strength it has for the provision of the rigidity to the polymer electrolyte membrane.

Sensor application

In search of the production of a quasi-solid-state dye-sensitized solar cell (DSSC) using a high conductivity polymer gel electrolyte, a suitable polymeric material was needed to be a host matrix in the composite. Therefore, PMMA was found to be a good and compatible polymer for this purpose. This was attributed to its mechanical strength, compatibility, and optical clarity[27].

Solar and nanotechnology applications

Due to the wider application of nanocomposites in the field of nanotechnology, many researchers focused their attention on nanocomposites, their fabrication, and applications. Perween et al. reported the use of PMMA and graphite to fabricate plastic chip electrodes (PCEs) via a simple solution casting method. This characterization was made using microscopy (SEM and AFM) as well as thermal properties (TGA), and mechanical and electrical properties. The fabricated electrode was economically inexpensive, multipurpose, and dispensable for various applications[28].

| [References]

- Malcom, P.S. Polymer Chemistry: An Introduction. 3rd ed.; Oxford University Press: NY, pp 167–176, 256–276.

- Henri, L. Thermohygroelastic Properties of Polymethylmethacrylate; 2007, Netherlands. pp. 11–13.

- Demir, M. M.; Memesa, M.; Castignolles, P.; Wegner, G. Macromolecular Rapid Communications. 2006, 27 (10), 763–770.

- Hashim, H.; Adam, N. I.; Zaki, N.H.M.; Mahmud, Z.S.; Said, C.M.S.; Yahya, M.Z.A.; Ali, A.M.M. Conference on Science and Social Research 2010 (CSSR 2010), Kuala Lumpur, Malaysia, 485–488.

- Henry, A.C.; Tutt, T.J.; Galloway, M.; Davidson, Y.Y.; McWhorter, C.S.; Soper, S.A.; McCarley, R.L. Analytical Chemistry 2000, 72(21), 5331–5337.

- Lee, L.H.; Chen, W.C. Chem. Mater. 2001, 15, 1137–1142.

- Shah, J. J.; Geist, J.; Locascio, L. E.; Gaitan, M.; Rao, M. V.; Vreeland, W. N. “Surface modification of poly(methyl methacrylate) for improved adsorption of wall coating polymers for microchip electrophoresis”, Electrophoresis 2006, 27(19), 3788–3796.

- Adhikari, B.; Majumdar, S. “Polymers in sensor applications”, Progress in Polymer Science 2004, 29(7), 699–766.

- Isha, A.; Yusof, N.A.; Ahmad, M.; Suhendra, D.; Yunus, W.M.Z.W.; Zainal, Z. Sensors and Actuators B: Chemical. 2006, 114(1), 344–349.

- Kost, J.; Langer, R. “Responsive polymeric delivery systems”, Advanced Drug Delivery Reviews. 2012, 64, 327–341.

- Beruto, D.T.; Botter, R.; Fini, M. Biomaterials. 2002, 23(12), 2509–2517.

- Shi, M.; Kretlow, J.D.; Spicer, P.P.; Tabata, Y.; Demian, N.; Wong, M.E.; Kasper, F.K.; Mikos, A.G. Journal of Controlled Release 2011, 152(1), 196–205.

- Mishra, S.; Sen, G. International Journal of Biological Macromolecules. 2011, 48(4), 688–694.

- Wang, M.; Pramoda, K.P.; Hong, S. Polymer 2005, 46, 11510–11516.

- George, O. Principles of Polymerization, 4th ed.; Wiley: NJ, 2004, pp 198–235.

- Wang, J.-S.; Matyjaszewski, K. Journal of the American Chemical Society. 1995, 117(20), 5614–5615.

- Grimaud, T.; Matyjaszewski, K. Macromolecules. 1997, 30(7), 2216–2218.

- Charles, A.H.; Edward, M.P. Plastics Materials and Processes, in Concise Encyclopedia; Wiley: NJ, 2003, pp. 42–44.

- Van Krevelen, D.W.; Nijenhuis, K. T. Properties of Polymers; Elsevier: Amsterdam, 2000, pp. 106, 322.

- Charles, A.H. Handbook of Plastics Processes; Wiley: NJ, 2006, pp. 1–7.

- Ishitake, K.; Satoh, K.; Kamigaito, M.; Okamoto, Y. Polymer Chemistry. 2012, 3(7), 1750–1757.

- Zuhair, J.; Abdul Amer, J.K.A.; Sura Fahim, A. “Chitosan/PMMA bioblend for drugs release applications”, International Journal of Engineering and Technology 2014, 4(5), 318–324.

- Tai, Y.; Wang, L.; Gao, J.; Amer, W.A.; Ding, W.; Yu, H. Journal of Colloid and Interface Science. 2011, 360(2), 731–738.

- Camara, R.M.; Portela, R.; Gutierrez-Martin, F.; Sanchez B. Global NEST Journal 2014, 6(3), 525–535.

- Haik, M.Y.; Ayesh, A.I.; Abdulrehman, T.; Haik, Y. Materials Letters. 2014, 124(0): 67–72.

- Hallinan, D.T.; Balsara, N.P. Polymer Electrolytes, in Annual Review of Materials Research, Vol 43, D.R. Clarke, Ed.; 2013, pp. 503–525

- Shen, J.; Li, Z.; Cheng, R.; Luo, Q.; Luo, Y.; Chen, Y.; Chen, X.; Sun, Z.; Huang, S. ACS Applied Materials & Interfaces 2014, 6(20), 17454–17462.

- Perween, M.; Parmar, D.B.; Bhadu, G.R.; Srivastava, D.N. “Polymer-graphite composite: a versatile use and throw plastic chip electrode”, Analyst 2014, 139(22), 5919–5926.

|

|

|