| Identification | More | [Name]

Ethyl vinyl ether | [CAS]

109-92-2 | [Synonyms]

Ethoxyethene

ETHOXYETHYLENE

ETHYL VINYL ETHER

VINAMAR

VINYL ETHYL ETHER

1-Ethoxyethene

1-Ethoxyethylene

agrisyntheve

CH2=CHOC2H5

ethene,ethoxy

Ethene,ethoxy-

Ethenylethylether

Ether, ethyl vinyl

Ether, vinyl ethyl

ether,ethylvinyl

ether,vinylethyl

ethoxy-ethen

Ethyl ethenyl ether

Ethyloxyethene

EVE | [EINECS(EC#)]

203-718-4 | [Molecular Formula]

C4H8O | [MDL Number]

MFCD00009248 | [Molecular Weight]

72.11 | [MOL File]

109-92-2.mol |

| Chemical Properties | Back Directory | [Appearance]

Colorless liquid. Extremely reactive, can

be polymerized in liquid or vapor phase. Slightly soluble in water (0.9% by weight). Commercial

material contains inhibitor to prevent premature

polymerization. Often stored underground

to minimize vapor losses. | [Melting point ]

-116 °C (lit.) | [Boiling point ]

33 °C (lit.) | [density ]

0.753 g/mL at 25 °C(lit.)

| [vapor pressure ]

560 hPa (20 °C) | [refractive index ]

n20/D 1.376(lit.)

| [Fp ]

−50 °F

| [storage temp. ]

Refrigerator | [solubility ]

8.3g/l | [form ]

Liquid | [color ]

Clear colorless | [Odor]

nauseating-ethereal but sweet odor | [Stability:]

Stable. Highly flammable. Incompatible with strong oxidizing agents. May form peroxides in storage-check for their formation before use. | [explosive limit]

1.3-12.0%(V) | [Water Solubility ]

7.8 g/L (25 ºC) | [Detection Methods]

GC | [BRN ]

605351 | [Exposure limits]

ACGIH: Ceiling 2 mg/m3

NIOSH: Ceiling 2 mg/m3 | [InChIKey]

FJKIXWOMBXYWOQ-UHFFFAOYSA-N | [LogP]

1.63 at 25℃ | [Uses]

Copolymerization, intermediate. | [CAS DataBase Reference]

109-92-2(CAS DataBase Reference) | [NIST Chemistry Reference]

Ethene, ethoxy-(109-92-2) | [EPA Substance Registry System]

109-92-2(EPA Substance) |

| Safety Data | Back Directory | [Hazard Codes ]

F+,Xi,F | [Risk Statements ]

R12:Extremely Flammable.

R19:May form explosive peroxides.

R36/37/38:Irritating to eyes, respiratory system and skin . | [Safety Statements ]

S16:Keep away from sources of ignition-No smoking .

S23:Do not breathe gas/fumes/vapor/spray (appropriate wording to be specified by the manufacturer) .

S26:In case of contact with eyes, rinse immediately with plenty of water and seek medical advice .

S3/7:Keep container tightly closed in a cool place .

S33:Take precautionary measures against static discharges .

S36:Wear suitable protective clothing . | [RIDADR ]

UN 1302 3/PG 1

| [WGK Germany ]

1

| [RTECS ]

KO0710000

| [F ]

19 | [Autoignition Temperature]

178 °C | [TSCA ]

Yes | [HazardClass ]

3 | [PackingGroup ]

I | [HS Code ]

29091900 | [Safety Profile]

Mddly toxic by

ingestion. Mutation data reported. A skin

irritant. A very dangerous fire and explosion

hazard when exposed to heat or flame; can

react vigorously with oxidizing materials. To

fight fire, use alcohol foam, foam, CO2, dry

chemical. Explosive polymerization is

catalyzed by methane sulfonic acid. When

heated to decomposition it emits acrid

smoke and irritating fumes. See also

ETHERS. | [Hazardous Substances Data]

109-92-2(Hazardous Substances Data) | [Toxicity]

LD50 orally in Rabbit: 6120 mg/kg LD50 dermal Rabbit > 15000 mg/kg |

| Hazard Information | Back Directory | [General Description]

A clear colorless low-boiling liquid (35-36°C) with an ether-like odor. Flash point below-50°F. May polymerize exothermically if heated or contaminated. If polymerization takes place inside a container, the container may rupture violently. Less dense than water and slightly soluble in water. Hence floats on water. Vapors are heavier than air. | [Reactivity Profile]

VINYL ETHYL ETHER(109-92-2) is a very dangerous fire and explosion hazard when exposed to heat or flame. Undergoes autooxidation with formation of peroxides in the air. Can react vigorously with oxidizing materials. Undergoes explosive polymerization in contact with methanesulfonic acid [Eaton, P. E. et al., J. Org. Chem., 1972, 37, p. 1947]. | [Air & Water Reactions]

Highly flammable. Slightly soluble in water. Tends to form explosively unstable peroxides when exposed to oxygen. | [Hazard]

Carcinogen. | [Health Hazard]

INHALATION OR INGESTION: Excitement followed by unconsciousness and respiratory paralysis. CNS depression. EYES: May cause irritation and transient injury to cornea. SKIN: Prolonged contact can cause tissue defatting and dehydration leading to dermatitis. | [Fire Hazard]

Behavior in Fire: Explosive hazard | [Chemical Properties]

Colorless liquid. Extremely reactive, can

be polymerized in liquid or vapor phase. Slightly soluble in water (0.9% by weight). Commercial

material contains inhibitor to prevent premature

polymerization. Often stored underground

to minimize vapor losses. | [Preparation]

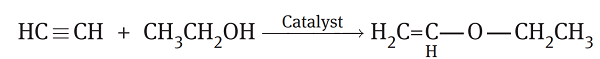

Ethyl vinyl ether (EVE) can be prepared by reacting acetylene with absolute ethanol in the presence of an alkali catalyst. The most commonly used catalyst for vinylation is an alkali metal hydroxide or an alkali metal alkoxide.

In China, three processes for the manufacture of EVE using the acetylene route were used:

A continuous process with a homogeneous catalyst under high pressure. The advantages of this process are fast reaction rate and high conversion, but the disadvantages include the requirement of high standard equipment, large energy consumption, and easy safety issues.

A process with a solid catalyst (heterogeneous catalyst) under atmospheric pressure is relatively simple in product separation and refining compared with a process with a homogeneous catalyst under high pressure. However, it has the disadvantages of low output, the short service life of catalyst (about 110 h), and a high requirement on the specification of carrier lime.

A process with a homogeneous catalyst under atmospheric pressure has the advantages of high output and good safety but disadvantages of low conversion.

In the process with solid catalyst under atmospheric pressure, acetylene, and ethanol vapor were introduced into a fixed-bed reactor, and the vinylation reaction was carried out at a temperature as high as about 180 °C. EVE was produced with a concentration of about 70% in the outlet gas stream from the reactor. The fixed-bed reactor was charged with 4–5 mesh catalyst particles of potassium hydroxide supported on lime.

| [Synthesis]

Ethyl vinyl ether is synthesized by bubbling Acetylene through Ethylalcohol in presence of Sodium ethoxide.

| [Purification Methods]

It usually contains polymerization inhibitors (usually amines, e.g. triethanolamine) which can be removed by fractional distillation. Redistil it from sodium. [Beilstein 1 IV 2049.] LACHRYMATORY. | [Toxics Screening Level]

The initial threshold screening level (ITSL) for Ethyl vinyl ether is 20 μg/m3 based on an annual averaging time. |

|

|