| 99% |

In chloroform; at 20℃; for 18h; |

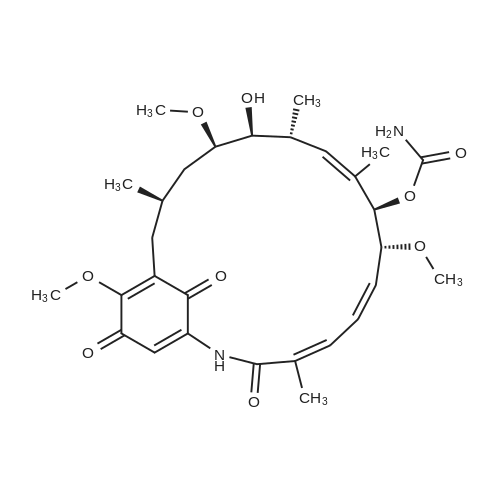

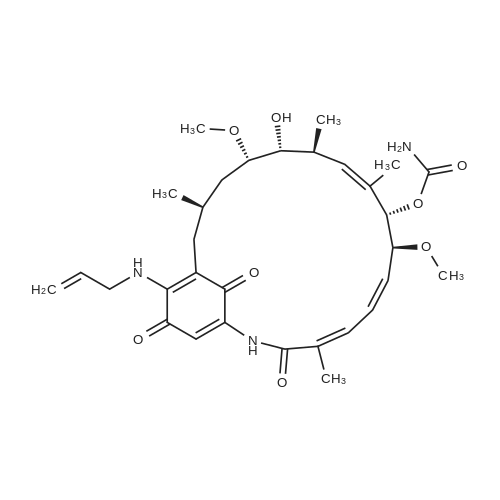

(+) -Geldanamycin (5.1 mg, 9. 0 mol) was stirred with allylamine (10.0 ul, 0.13 mmol) in chloroform (1.5 ml) at room temperature. Upon the complete conversion of GA shown by thin layer chromatography (18 hours), the mixture was washed with brine, dried over anhydrous sodium sulfate, and concentrated. Separation by flash column chromatography on silica gel (hexane/ethyl acetate) gave the product as a purple solid (5.3 mg, 99%). IR (KBr) (can~') 3464,3333, 2958,2929, 2825,1728, 1691,1652, 1571,1485, 1372,1323, 1189,1101, 1057; UV (95% EtOH) (nm) 332 (s = 2. 0 x 104) ;'H NMR (CDC13, 500 MHz) 8 9. 14 (s, 1H), 7.28 (s, 1H), 6.93 (bd, J= 11.5 Hz, 1H), 6.56 (bdd, J= 11. 5,11. 0 Hz, 1H), 6.38 (bt, J= 6. 0 Hz, 1H), 5.94-5. 81 (m, 3H), 5.30-5. 24 (m, 2H), 5.17 (s, 1H), 4.82 (bs, 2H), 4.29 (bd, J= 10.0 Hz, 1H), 4.21 (bs, 1H), 4.18-4. 08 (m, 2H), 3.55 (ddd, J= 9.0, 6.5, 2.0 Hz, 1H), 3.43 (ddd, J= 9.0, 3.0, 3.0 Hz, 1H), 3. 34 (s, 3H), 3.25 (s, 3H), 2.72 (dqd, J= 9.5, 7.0, 2.0 Hz, 1H), 2.63 (d, J= 14.0 Hz, 1H), 2.34 (dd, J= 14. 0,11. 0 Hz, 1H), 2.00 (bs, 3H), 1.78 (d, J= 1.0 Hz, 3H), 1.78-1. 74 (m, 2H), 1.74-1. 67 (m, 1H), 0.99-0. 95 (m, 6H) ; 3C NMR (CDC13, 125 MHz, assignment of protonated carbons aided by DEPT) 8 183.8 (18-C), 180.9 (21-C), 168.4 (1-C), 156.0 (7- OzCNHz), 144.6 (17-C), 141.2 (20-C), 135.8 (5-C), 134.9 (2-C), 133.7 (9-C), 132.7 (8-C), 132.5 (3'-C), 126.9 (4-C), 126.5 (3-C), 118.5 (3'-C), 108.8 (19-C), 108.7 (16-C), 81.6 (7-C), 81.4 (12-C), 81.2 (6-C), 72.6 (11-C), 57.1 (6-or 12-OCH3), 56.7 (6-or 12-OCH3), 47.8 (1'-C), 35.0 (13-C), 34.3 (15-C), 32.3 (10-C), 28.4 (14-C), 22.9 (14-CH3), 12.8 (8-CH3), 12.6 (2-CH3), 12.3 (10-CH3); HRMS (FAB) found 586.3120 [M+H] +, calcd. 586.3129 for C31H44N30g. |

| 95% |

In dichloromethane; at 23℃; |

17-AAG was synthesized in the lab from geldanamycin (GA) (LC Laboratories, Woburn, MA). Briefly, 100 mg of GA (0.2 mmol) was dissolved in 2 mL of dry CH2Cl2. Next, 5 equivalents of allylamine (57.1 g/mol, d = 0.763 g/mL) was added dropwise to the flask. The reaction was stirred at room temperature (RT; ?23 C) under low light until complete by TLC analysis (approx. 2 days) (95:5 CHCl3:MeOH, Rf 0.21), precipitated with hexane (3x), centrifuged at 2000 g's for 15 minutes, and evaporated to dryness. Yield: 95 mg, 95%; MS m/z 584 (M-); 1H NMR (CDCl3) delta 0.99 (m, 6H, 10-Me, 14-Me), 1.25 (t, 1H, H-13), 1.60-1.85 (br m, 6H, H-13, H-14, 8-Me), 2.05 (s, 3H, 2-Me), 2.46 (br m, 2H, H-15), 2.83-2.90 (br m, 3H, H-10), 3.27 (s, 3H, OMe), 3.36 (s, 3H, OMe), 3.40 (t, 1H, H-12), 3.58-3.68 (br m, 2H, H-11, H-23), 4.31 (d, 1H, H-7), 5.10 (br s, 1H), 5.21-5.55 (br m, 3H, H-9, H-24), 5.86-5.99 (br t, 2H, H-5, H-23), 6.59 (t, 1H, H-4), 6.94 (d, 1H, H-3), 7.28 (br s, 1H, H-19). |

Chemistry

Chemistry

Pharmaceutical Intermediates

Pharmaceutical Intermediates

Inhibitors/Agonists

Inhibitors/Agonists

Material Science

Material Science

For Research Only

For Research Only

120K+ Compounds

120K+ Compounds

Competitive Price

Competitive Price

1-2 Day Shipping

1-2 Day Shipping