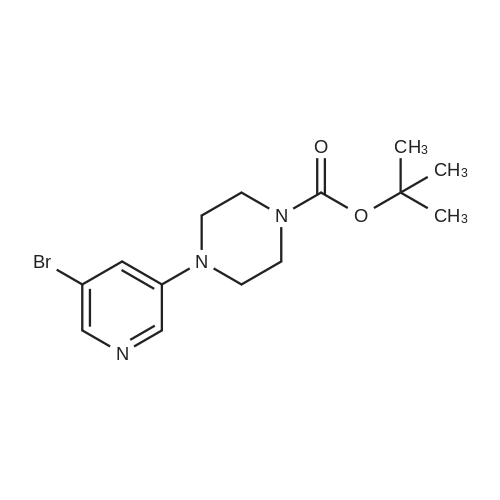

| 60% |

With KF;palladium diacetate; In tetrahydrofuran; |

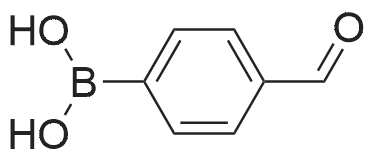

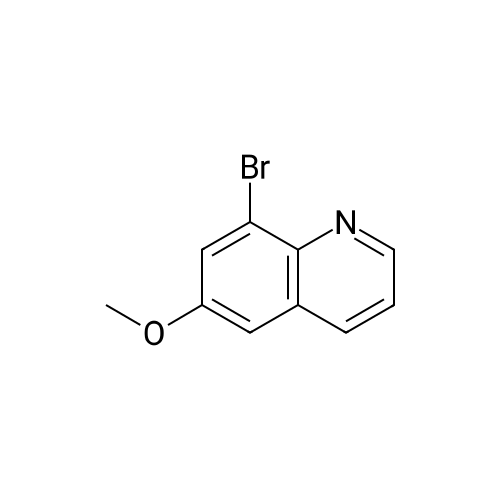

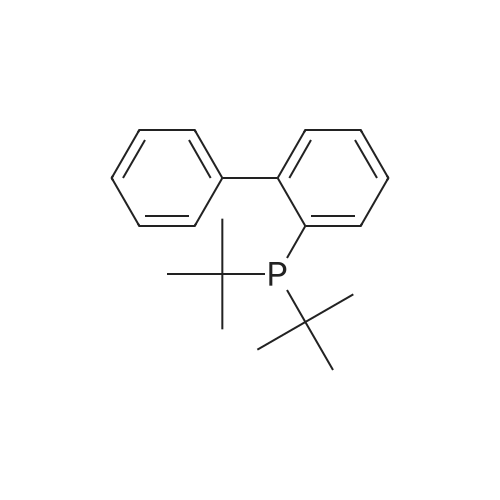

(4'-Formylbiphenyl-3-ylmethyl)-carbamic acid 9H-fluoren-9-ylmethyl ester (S30). 4-Formylphenylboronic acid (5.0 g, 33 mmol), aryl bromide S27 (9.0 g, 22 mmol), KF (3.8 g, 66 mmol), <strong>[224311-51-7]biphenyl-2-yl-di-tert-butyl-phosphane</strong> (0.26 g, 0.88 mmol), and palladium(II) acetate (0.099 g, 0.44 mmol) were charged into an oven-dried flask. After one evacuation/backfill cycle with Ar, the solids were dissolved in THF (45 mL) and heated to reflux with stirring. After 5 h, the reaction was diluted with ethyl acetate, filtered through a celite pad and washed with 1 M NaOH. The aqueous layer was extracted with ethyl acetate and the combined organics were then washed with brine, dried over MgSO4, filtered, and concentrated in vacuo to afford an orange oil (13 g). The crude oil was purified by flash column chromatography (silica gel, 30percent ethyl acetate/hexanes) to obtain aldehyde S29 as a yellow oil (5.7 g, 60percent). 1H NMR (400 MHz, CDCl3): delta10.06 (s, 1H), 7.95 (d, 2H, J=8.2 Hz), 7.76 (d, 2H, J=7.5 Hz), 7.74 (d, 2H, J=8.2 Hz), 7.59 (d, 2H, J=7.5 Hz), 7.56 (m, 1H), 7.55 (s, 1H), 7.46 (dd, 1H, J=7.9 Hz, 7.9 Hz), 7.39 (dd, 2H, J=7.5 Hz, 7.5 Hz), 7.33 (m, 1H), 7.29 (dd, 2H, J=7.5 Hz, 7.5 Hz), 5.16 (broad s, 1H), 4.48 (d, 2H, J=7.0 Hz), 4.47 (s, 2H), 4.24 (t, 1H, J=7.0 Hz). ESI/MS: 456 (M+Na+). |

| 60% |

With KF;palladium diacetate; In tetrahydrofuran; |

(4'-Formylbiphenyl-3-ylmethyl)-carbamic acid 9H-fluoren-9-ylmethyl ester (S30). 4-Formylphenylboronic acid (5.0 g, 33 mmol), aryl bromide S27 (9.0 g, 22 mmol), KF (3.8 g, 66 mmol), <strong>[224311-51-7]biphenyl-2-yl-di-tert-butyl-phosphane</strong> (0.26 g, 0.88 mmol), and palladium(II) acetate (0.099 g, 0.44 mmol) were charged into an oven-dried flask. After one evacuation/backfill cycle with Ar, the solids were dissolved in THF (45 mL) and heated to reflux with stirring. After 5 h, the reaction was diluted with ethyl acetate, filtered through a celite pad and washed with 1 M NaOH. The aqueous layer was extracted with ethyl acetate and the combined organics were then washed with brine, dried over MgSO4, filtered, and concentrated in vacuo to afford an orange oil (13 g). The crude oil was purified by flash column chromatography (silica gel, 30percent ethyl acetate/hexanes) to obtain aldehyde S29 as a yellow oil (5.7 g, 60percent). 1H NMR (400 MHz, CDCl3): delta10.06 (s, 1H), 7.95 (d, 2H, J=8.2 Hz), 7.76 (d, 2H, J=7.5 Hz), 7.74 (d, 2H, J=8.2 Hz), 7.59 (d, 2H, J=7.5 Hz), 7.56 (m, 1H), 7.55 (s, 1H), 7.46 (dd, 1H, J=7.9 Hz, 7.9 Hz), 7.39 (dd, 2H, J=7.5 Hz, 7.5 Hz), 7.33 (m, 1H), 7.29 (dd, 2H, J=7.5 Hz, 7.5 Hz), 5.16 (broad s, 1H), 4.48 (d, 2H, J=7.0 Hz), 4.47 (s, 2H), 4.24 (t, 1H, J=7.0 Hz). ESI/MS: 456 (M+Na+). |

Chemistry

Chemistry

Pharmaceutical Intermediates

Pharmaceutical Intermediates

Inhibitors/Agonists

Inhibitors/Agonists

Material Science

Material Science

For Research Only

For Research Only

120K+ Compounds

120K+ Compounds

Competitive Price

Competitive Price

1-2 Day Shipping

1-2 Day Shipping