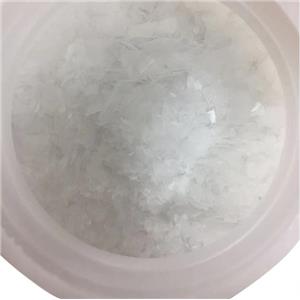

Release powder NEW

| Price | $1.98 |

| Package | 1kg |

| Min. Order: | 100kg |

| Supply Ability: | 20T |

| Update Time: | 2024-06-11 |

Product Details

| Product Name: Release powder | Min. Order: 100kg |

| Purity: 99.5% | Supply Ability: 20T |

| Release date: 2024/06/11 |

Product description

Product introduction:

Swiss stripping powder is a powdered stripping agent, mainly used to remove the photosensitive glue on the screen. 100 grams of stripping powder is mixed with 5-8L water or sprinkled directly on the screen, then repeatedly scrubbed with cotton cloth or sponge to make the photosensitive glue completely fall off, and finally rinsed with clean water. If ghost images are still found in the printed area, ghost removal agents can be used to remove them. The most significant advantage of using stripping powder is that it greatly improves the regeneration rate of the screen and saves mesh cloth, thereby reducing the plate making cost for the enterprise.

Packaging specifications: 100G/bottle, 1KG/bottle, 15KG/barrel, 25KG/barrel

Method of application

50g of stripping powder is mixed with 950g of water. After mixing, you can directly apply it on both sides of the screen with a screen brush, or soak it directly for 2-5 minutes, and then scrub it with a cloth or a special brush to completely remove the photosensitive glue. Finally, rinse it with clean water. If you find that there are still ghosts in the printed area, you can use screen oil or ghost removal agent to remove them. Dissolution of stripping powder:

▲Put an appropriate amount of stripping powder in a beaker and break the block of stripping powder with a glass rod.

▲Pour an appropriate amount of distilled water, stir and dissolve it with a glass rod, and pour the dissolved part into the container. Repeat the above steps for the undissolved part until it is completely dissolved.

▲Calculate according to the concentration of 3%, add enough distilled water, shake well and it can be used.

Usage (I):

Use a sponge to take a small amount of stripping solution and apply it evenly on both sides of the screen. It is best to use a stripping brush to rub the surface of the screen back and forth until the photosensitive film dissolves and falls off. Rinse the screen with a high-pressure water gun. If necessary, repeat the above operation.

Some screens (such as printed screens or water-based screens that have been stored for a long time) will still have patterns on the screen after stripping (also known as ghosting). At this time, ghost removal liquid should be used to rinse the screen clean.

Note: All chemical products should be tested before use to ensure the effectiveness of use. Water-based screens that have been used with hardened water cannot be stripped.

Usage (II):

1. First use 100g of stripping powder and add 3-5 liters of water. If the effect is too strong, add more water appropriately.

2. Remove the residual ink and screen-sealing slurry on the screen.

3. Brush the stripping water on both sides of the screen until the photosensitive glue dissolves.

4. Rinse it clean with a high-pressure water gun.

Company Profile Introduction

You may like

Recommended supplier

| Product name | Price | Suppliers | Update time | |

|---|---|---|---|---|

| $0.00/25kg |

VIP1Y

|

Qixia Lu Feng Industry and Trade Co Ltd

|

2025-03-07 | |

| $40.00/1KG |

VIP1Y

|

Shandong Xuhuang New material CoLTD

|

2025-02-21 | |

| $0.00/1kg |

VIP3Y

|

Changsha Staherb Natural Ingredients Co., Ltd.

|

2022-09-01 |

- Since: 2023-04-24

- Address: Room 010, House 308, No. 350, Juhuashan Road, Huangdao District, Huangdao City, Shandong Province

China

China