| Identification | Back Directory | [Name]

Silicone oil | [CAS]

63148-62-9 | [Synonyms]

ko08

pdms

HMDO

KS66

DC510

dc35a

dc35b

dc360

pns25

sf-96

pms300

sdc200

pms1.5

pms154a

pms200a

sf-1098

siloxane

silakm10

silastic

baysilon

Silicone

ucliquidg

xf-13-563

slytermxlt

SF 96Silic

Silicone200

syltherm800

silicone360

siliconel-45

antifoamfd62

Silicone oil

DC-200Silicon

dowcorning200

siliconedc360

dowcorning561

SILICONE FLUID

Silicone oil I

dimethyl-siloxan

Silicone emulsion

dowcorning200fluid

dowcorning360fluid

siliconedc360fluid

siliconereleasel45

si-o-silss-101-350

silikonantifoamfd62

unioncarbideliquidg

OLEIC ACID PURIFIED

Silicone oil PMX-200

I,II,IIISilicone oil

DiMethylsilcone fluid

Dow Corning BY 25-320

Levelling foamer L108

polydimethylsiloxanes

Dimethylsiliconeoil201

dimethylsilicone fluid

Hexamethyloxy disilane

Poly(dimethylsiloxane)

DIETHYL ETHER RECTIFIED

dimethylsilicone fluid

BIS(TRIMETHYLSILYL)ETHER

MethylsiliconeresinJS-01

emulsifying silicone oil

SILICONOIL PHARMA 100 CST.

LINEARPOLYDIMETHYLSILOXANES

Siloxanesandsilicones,di-Me

poly[oxy(dimethylsilylene)]

solarheat-transferfluidsf-96

POLYDIMETHYLSILOXANE,粘度10CST

dimethylsiliconesandsiloxanes

Dimethylsiloxanesandsilicones

SILICONE OIL DC 200, ~10 MPA.S

Silicone liquid, low viscosity

SILICONE OIL DC 200, ~20 MPA.S

SILICONE OIL DC 200, ~50 MPA.S

SILICONE OIL 47 V 50 RHODORSIL

Hexamethyldisiloxane solution

diMethylsilicone fluid DC 200

SILICONE OIL DC 200, ~500 MPA.S

SILICONE OIL DC 200, ~100 MPA.S

SILICONE OIL DC 200, ~1000 MPA.S

DiMethyl silicone oil (201grade)

SILICONE OIL DC 200, ~30000 MPA.S

SILICONE OIL DC 200, ~60000 MPA.S

Silicone oilPoly(dimethylsiloxane)

Silicone oil viscosity 5 cSt (25 C)

ETHYL ACETATE PESTINORM SUPRA TRACE

SILICONE OIL, FOR MP & BP APPARATUS

Silicone oil viscosity 50 cSt (25 C)

Silicone oil viscosity 20 cSt (25 C)

Silicone oil viscosity 10 cSt (25 C)

Silicone oil viscosity 100 cSt (25 C)

Silicone oil viscosity 500 cSt (25 C)

Silicone oil viscosity 350 cSt (25 C)

SILICON OIL 550 FOR GAS CHROMATOGRAPHY

Silicone oil viscosity 1,000 cSt (25 C)

METHYLENE BLUE CHLORIDE 3H2O REAGENT GR

SILICONE OIL, FOR OIL BATHS UP TO 180 C

SILICONE OIL DC 200, ~350 MPA.S, FOR GC

POLY(DIMETHYLSILOXANE) 200 FLUID &

Silicone oil viscosity 30,000 cSt (25 C)

Silicone oil viscosity 10,000 cSt (25 C)

Silicone oil DC 200,Polydimethylsiloxane

Silicone liquid, for heating baths, pure

Silicone oil viscosity 100,000 cSt (25 C)

2,2,4,4-TETRAMETHYL-3-OXA-2,4-DISILAPENTANE

SILICONE OIL, HIGH TEMPERATURE, FOR OIL BATHS

Dimethyl siloxane: (Syltherm XLT: Silicone 360)

Silicone oil, for oil baths, range -40 to +200°C

Silicone oil viscosity ~60,000 mPa.s, neat(25 C)

SILICONE OIL, FOR OIL BATHS FROM -50 C T O + 200 C

Silicone Oil, for oil baths, Type No. H201-350, 250℃

Polydimethylsiloxane, trimethylsiloxy terminated, 1.5 cSt

POLY(DIMETHYLSILOXANE), 200 FLUID, VISCO SITY 5 CENTISTOKES

Silicone oil, for oil baths, usable range froM -40 to +200°C

POLY(DIMETHYLSILOXANE), 200 FLUID, VISCO SITY 10 CENTISTOKES

POLY(DIMETHYLSILOXANE), 200 FLUID, VISCO SITY 50 CENTISTOKES

POLY(DIMETHYLSILOXANE), 200 FLUID, VISCO SITY 20 CENTISTOKES

POLY(DIMETHYLSILOXANE), 200 FLUID, VISCO SITY 350 CENTISTOKES

POLY(DIMETHYLSILOXANE), 200 FLUID, VISCO SITY 500 CENTISTOKES

POLY(DIMETHYLSILOXANE), 200 FLUID, VISCO SITY 100 CENTISTOKES

Silicone oil, for melting point and boiling point apparatuses

POLY(DIMETHYLSILOXANE), 200 FLUID, VISCO SITY 1,000 CENTISTOKES

POLY(DIMETHYLSILOXANE), 200 FLUID, VISCO SITY 30,000 CENTISTOKES

POLY(DIMETHYLSILOXANE), 200 FLUID, VISCO SITY 60,000 CENTISTOKES

POLY(DIMETHYLSILOXANE), 200 FLUID, VISCO SITY 10,000 CENTISTOKES

POLY(DIMETHYLSILOXANE), 200 FLUID, VISCO SITY 12,500 CENTISTOKES

Silicone oil, for Melting point and boiling point apparatuses 1KG

POLY(DIMETHYLSILOXANE), 200 FLUID, VISCO SITY 100,000 CENTISTOKES

Silicone oil, for Melting point and boiling point apparatuses 500GR

Polydimethylsiloxane, trimethylsiloxy terminated, viscosity 20 cSt.

Polydimethylsiloxane, trimethylsiloxy terminated, viscosity 10 cSt.

Polydimethylsiloxane, trimethylsiloxy terminated, viscosity 100 cSt.

Polydimethylsiloxane, trimethylsiloxy terminated, viscosity 3.0 cSt.

Polydimethylsiloxane, trimethylsiloxy terminated, viscosity 500 cSt.

Polydimethylsiloxane, trimethylsiloxy terminated, viscosity 7.0 cSt.

Polydimethylsiloxane, trimethylsiloxy terminated, viscosity 350 cSt.

Polydimethylsiloxane, trimethylsiloxy terminated, viscosity 5.0 cSt.

Polydimethylsiloxane, trimethylsiloxy terminated, viscosity 1.000 cSt.

Polydimethylsiloxane, trimethylsiloxy terminated, viscosity 5.000 cSt.

Polydimethylsiloxane, trimethylsiloxy terminated, viscosity 12.500 cSt.

Polydimethylsiloxane, trimethylsiloxy terminated, viscosity 10.000 cSt.

Silicone oil Dow Corning Corporation 200(R) fluid, viscosity 60,000 cSt (25 C) | [EINECS(EC#)]

203-492-7 | [Molecular Formula]

C6H18OSi2 | [MDL Number]

MFCD00008265 | [MOL File]

63148-62-9.mol | [Molecular Weight]

162.38 |

| Chemical Properties | Back Directory | [Definition]

Any of a large group of siloxane polymers based on a

structure consisting of alternate silicon and oxygen

atoms with various organic radicals attached to the

silicon:

| [Appearance]

viscous colourless liquid | [Melting point ]

−59 °C(lit.)

| [Boiling point ]

101 °C(lit.)

| [density ]

0.963 g/mL at 25 °C | [Tg]

-123 | [vapor density ]

>1 (vs air)

| [vapor pressure ]

<5 mm Hg ( 25 °C)

| [refractive index ]

n20/D 1.377(lit.)

| [Fp ]

33 °F

| [storage temp. ]

2-8°C | [solubility ]

Chloroform (Slightly), Ethyl Acetate (Sparingly), Toluene (Sparingly) | [form ]

Oily Liquid | [color ]

Clear colorless | [Specific Gravity]

0.853 | [Odor]

Odorless | [Stability:]

Stable. Incompatible with strong oxidizing agents. | [Water Solubility ]

PRACTICALLY INSOLUBLE | [Merck ]

14,8495 | [Dielectric constant]

2.7(Ambient) | [Uses]

(Liquid) Adhesives, lubricants, protective coat-

ings, coolants, mold release agents, dielectric

fluids, heat transfer, wetting agents and surfac-

tants, foam stabilizer for polyurethanes, diffusion

pumps, antifoaming agent for liquids, textile fin-

ishes, water repellent, weatherproofing concrete,

brake fluids, cosmetic items, polishes, foam shields

in solar energy collectors, rust preventives. (Resin)

Coatings, molding compounds, laminates (with

glass cloth), filament winding sealants, room-

temperature curing cements, electrical insulation,

impregnating electric coils, bonding agent, modifier

for alkyd resins, vibration-damping devices. (Elas-

tomer, or silicone rubber) Encapsulation of elec-

tronic parts; electrical insulation; gaskets; surgical

membranes and implants; automobile engine com-

ponents; flexible windows for face masks, air locks,

etc.; miscellaneous mechanical products.

| [EPA Substance Registry System]

Siloxanes and Silicones, di-Me(63148-62-9) |

| Questions And Answer | Back Directory | [Oily linear polysiloxane]

Silicone oil is a kind of oily linear polysiloxane produced from the hydrolysis and poly-condensation of chlorotrimethylsilane, ethyl chlorosilane, and phenyl chlorosilane containing mono-functional group and bifunctional group. The commonly called silicone oil means the polydimethylsiloxane and polymethyl phenyl siloxane. Silicone oil is a kind of colorless, odorless, non-toxic, transparent, non-volatile liquid with non-corrosive effect on metal, low freezing point and good anti-water property and moisture resistance, low surface tension and being capable of being resistant to dilute acids and bases and has wide application in various national economy departments.

The viscosity of the silicone oil has small changes with temperature. At-60~250 °C, it can be used as a lubricant agent for sextant, electromotor, shells aiming system and shipborne radar devices. When being mixed with thickener such as carbon black and lithium stearate, it can be used for preparation of viscous grease for being applied to vacuum or high temperature sealing systems and the sealing of vacuum cocks, bushings, and valve. It will not be cured by high compression with a relative high compressibility and can be used as liquid springs of aircraft and used for eliminating flutter in the buffer, shock absorption system to maintain the stability of the gauge pointer in aircraft cabin and damping of damper device. Because of its non-corrosiveness on metal and long lifespan, it is widely used as hydraulic pressure fluid in various kinds of delivery systems such as being the hydraulic pressure fluid of aircraft landing gear, flaps, doors, and speed brakes; Because of its small density, low viscosity, it can decrease the weight of the hydraulic pressure systems of the aircraft system by 45% compared with the mineral oil system.

It is heat resistant and can be used as the heat transfer medium of-50~250 ℃; it does not absorb moisture and has excellent electrical insulation and can resist high temperature to be used as a dielectric liquid for being applied to the capacitors and the miniature transformer of encapsulating and impregnating. It is permeable to visible light and can be coated to the lens and optical glass to improve the light transmission properties; its being coated to the motion picture film can reduce the friction and extend the lifespan of the film. It has a good water resistance and can be used for processing wool, rayon, nylon, cotton fabric and can be used for making waterproof fabric; it has a low surface tension and can be used for plastic and rubber mold releasing agents; in the food and textile industry, it can be used in defoamers. Dimethyl silicone is non-toxic with physiologically inertia and can be used for the treatment of flatulence and can also play a role of skin care when added to cosmetics.

| [Product Features]

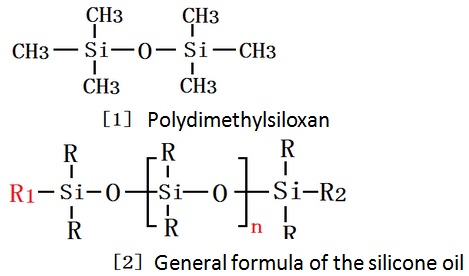

Silicone oil having a silica structure and is liquid at room temperature and is called as siloxane, referred as silicone oils. The simplest polydimethylsiloxane is as formula [1]. In [2], if the R, R1, R2 are all methyl groups, it is called α, ω-trimethylsilyloxy polydimethylsiloxane, that’s the commonly called silicone oil. It is a linear polymer of a low molecular weight. If R1 and R2 are not a methyl group, then it is not related to this article. Silicone oil is a colorless or light yellow transparent liquid and is odorless and tasteless. It has a high boiling point and low freezing point. The silicon-oxygen bond is very stable.

Silicone oil has the following features:

① low surface tension which is generally less than 209J/cm2 and is lower compared with the water and general surfactant;

② it has low solubility in water and oil with high activity. This feature allows that only a very small amount of silicone oil can already capable of reducing the surface tension of water;

③ It has high stability upon heating and oxygen; This feature allows the silicone oil can be used at high temperature without being subject to decomposition;

④ It has low volatility, and is chemically inert, for example, dimethicone with a viscosity of 3 × 10-2m2/s (20 ℃) ??has a vapor pressure at 100 ℃ as low as only being 6.67 mPa while this value is 40 mPa at 220 ℃. Moreover, it generally does not react with other substances;

⑤ It has high flash point and flame retardancy;

⑥ It has excellent electrical insulation ability with mold release property and anti-foaming property;

⑦ It has no physiological toxicity. Oral Mice LD50:100000 mg/kg, intravenous injection-dog LD50: 1.0ml/kg.

| [Organic silicone oil]

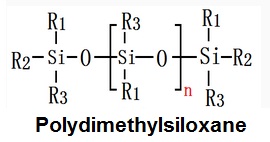

Silicone oil is also known as organic silicone oil. They are one kind of silicone polymers. It is made through hydrolysis of organic silicon with mono-functional group or bifunctional group to form the corresponding mono-, di-silanol with silanol further interacting with each other under acidic conditions to form the cyclic or chain-like polymers, which are further subject to poly-condensation reaction at atmospheric pressure and vacuum conditions to produce silicone oil with certain molecule weight. Silicone oil is an organic compound with closed end groups; it has the structure formula as follows:

Wherein R1, R2, R3 may be the either same of different organic groups such as methyl, ethyl, phenyl, vinyl, methoxy, ethoxy, and hydrogen. Those different groups result in different kind of silicone oil.

Silicone oil is a colorless, oily substance with its viscosity being able to be formulated as well as having a relatively low freezing temperature. Moreover, its viscosity only changes little with temperature changes. It also has high thermal stability and is not subject to decomposition at high temperature. The end of its chain can’t be subject to further poly-condensation reaction. When being heated to above 400 ℃, it generates low molecular weight products with the bond between the methyl group and the silicon atom being not broken during the thermal decomposition process. Silicone oil also has water resistance as well as electrical insulation resistance with volume resistivity being higher than 1015Ωcm and permittivity ε = about 2.58. It has a low surface tension and is non-toxic. Low molecular weight silicone oil can be taken as Newtonian fluids with gradually shifting toward pseudoplastic fluids upon increasing molecular weight. Silicone oil has a low vapor pressure and high compressibility. It has no corrosion on the metal and is very stable against the vast majority of organic reagents. It has good compatibility with mineral oil and is resistant to dilute acid and alkali.

Silicone oil is often used as advanced lubricants, anti-shock oil and insulating oil. It is also used as defoamers, mold releasing agents and the polishing agent of furniture, flooring, and automobile polish as well as the internal lubricants upon plastic processing. It also serves as a heat carrier, anti-vibration damping materials, cosmetics additives, medical polymer materials and glass fiber processing agents.

The above information is edited by the Chemicalbook of Dai Xiongfeng.

| [Transformer insulating oil]

Silicone oil is an excellent kind of transformer insulating oil with high heat resistance and high flash point. It is not easy to be subject to oxidation and combustion with its long-term working temperature being as high as 200 ℃. Silicone oil can tolerate electric arc, corona. Moreover, the value its dielectric loss factor can keep nearly constant over a wide temperature range (-40~110 ℃) and frequency range (103~108Hz). In addition, it also has good viscosity-temperature, low freezing point, and low volatility and is non-toxic without contaminating the environment and so on. The disadvantage of silicone oil is its great dielectric loss, being easy for hydrolysis and relative high prices and so on. Currently the silicone oil variety frequent application and good efficacy is "polydimethylsiloxane." Silicone oil is easily soluble in water and can also have reaction with the relevant components of the reaction in the air. So it should be tightly sealed during the application process. In addition, it is also necessary to take measures to prevent moisture and air intrusion.

| [Silicone oil for lubricating oil]

It can be used as the anti-foam agents for oil as well as for synthesizing lubricating oil. Silicone oil is made from Si-O chain and organic compound. It is a kind of odorless, tasteless organic liquid with a high chemical stability, low freezing point, low volatility and excellent anti-oxidation property and resistance to high temperature. It has been over 50 years since at early time when polydimethylsiloxane (referred as silicone oil) was used as an anti-foaming agent. Only if the silicone oil in the lubricating oil is in its insoluble state can it have anti-foaming. In contrast, if it is in a dissolved state, it not only has no anti-foaming property but also plays a role of foaming agent. Therefore, it is very important to choose silicone oil with proper viscosity. It is general to choose the silicon oil with 100~100000mm2/s (25 ℃) viscosity for being the anti-foaming agent. The low viscosity silicone oil is easily to be dispersed to exhibit anti-foaming property, however with large solubility and poor anti-foam persistence; high viscosity silicone oil has a poor anti-foaming property but excellent continuity. In order to draw on the strength of each other, people often mix two kinds of high and low viscosity silicone oil for using in combination. The general applied amount is around 10mg/kg.

Methyl silicone oil is produced from the following process: methyl chloride is first reacted with silicon in the presence of copper as the catalyst for generating into chloromethyl silane mixture. Then we further obtain methyl silane through hydrolysis; the methyl silane is further polymerized to obtain methyl with either acid or alkali catalyst. It is an excellent kind of anti-foaming agent with small usage amount and significant efficacy. It has wide applications and is commonly used in internal combustion engine oils and industrial lubricants. For highly dispersing it in the oil, first dissolve the silicone oil in a solvent (such as kerosene) into the concentrate liquid, and then stir and disperse it into the oil. Poor dispersion will result in poor anti-foam effect. Therefore, silicone oil anti-foaming agent is very sensitive to the blending technology.

Reference: Wang Daquan “Fine Chemicals Dictionary” Beijing: Chemical Industry Press .1998, page 843.

| [Chemical Properties]

It is milk-white viscous liquid and is non-volatile and odorless. It has a relative density of O.98~1.02. It is miscible with benzene, gasoline and other kinds of chlorinated hydrocarbons, aliphatic and aromatic hydrocarbons; it is not soluble in methanol, ethanol and water, but can be dispersed in water. It is Non-flammable, non-corrosive and is chemically stable. ADI: 0~1.5mg /start (FAO/WHO, 1994).

| [Uses]

It can be used as emulsifiers. China has provided that it can be applied during the fermentation process with the maximum usage amount being 0.2g/kg.

It can be used as advanced lubricants, anti-vibration oil, insulating oil, defoamers, release agents, polishes and vacuum diffusion pump oil.

It can be used as the paint for prevention of moisture and rust of metal surface. It can also be used as the coating for the surfaces of buildings for prevention of water.

It is used as hardening polyurethane foams additive.

| [Production method]

The Poly methyl siloxane and gas-phase silicon dioxide are mixed and crushed using roller to silica grease, then add polyoxyethylene alcohol, Tween 80 and deionized water for emulsion to generate it.

|

| Hazard Information | Back Directory | [Production Methods]

Silicone elastomers are generally prepared from chlorosilanes.

The chlorosilanes are hydrolyzed to give hydroxyl compounds that condense to form elastomers. Applications

include electrical insulation, gaskets, surgical membranes

and implants, and automobile engine components. | [General Description]

Silicone oil is low viscosity liquid polymerized siloxanes with organic side chains. | [Biological Activity]

Silicone oil is suitable for use in under-oil screenings of proteins. | [Solubility in organics]

Aliphatic and chlorinated hydrocarbons, THF, toluene | [Toxics Screening Level]

The ITSL for dimethyl silicones and siloxanes (CASRN 63148-62-9) is 2 μg/m3 based on annual averaging. |

|

|